Plywood Production Lathe for Woodworking CNC Machinery Veneer Peeling Machine Line

Overview Package size per unit product 380.00cm * 170.00cm * 190.00cm Gross weight per unit product 4200.000kg Product D

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 4ft |

| Automatic | Automatic |

| Certification | CE, ISO |

| Voltage | 220V/380V/415V/Customzied |

| Power | 41.4kw |

| Peeling Knife | 1500*180*16mm |

| Thickness Range | 0.3mm -4.0mm |

| Processing Wood Length | 970mm--1270mm |

| Processing Wood Diameter | Max500mm--Wood Core 28mm |

| Peeling Speed | 60m--150m Adjust Speed |

| Transport Package | Other Packaging |

| Specification | 4300*1600*1900 |

| Trademark | realgold/rotategold |

| Origin | China |

| HS Code | 8465960000 |

| Production Capacity | 300PCS/Month |

Packaging & Delivery

Package size per unit product 380.00cm * 170.00cm * 190.00cm Gross weight per unit product 4200.000kgProduct Description

Product Parameters

| Description | Unit | Parameter |

| Processing log length | mm | 970mm--1270mm |

| Processing log diameter | mm | 500mm maximum--28mm minimum |

| Processing range thickness | mm | 0.3mm--4.0mm |

| Host line speed | m/min | 45m--120m speed regulation |

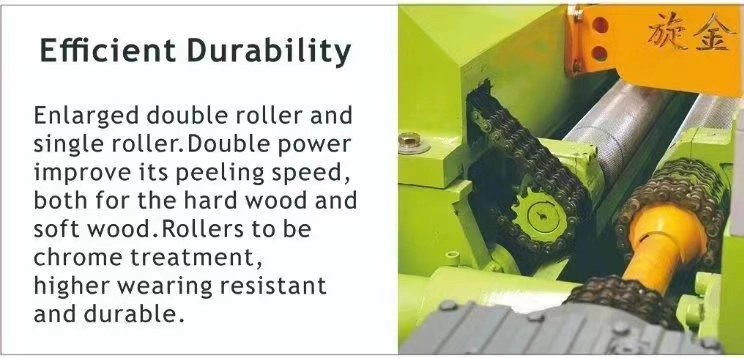

| Main and auxiliary motor power | kw | Double roller motor 11kw;Single roller motor 5.5kw+5.5kw. |

| Feed motor 11kw servo;Shear motor 2.2kw servo. | ||

| Conveying motor 1.5kw;Hydraulic knife clamping motor 4kw. | ||

| total power | kw | 41.4kw |

| Reducer model | R87 | Single and double roller motor and feed motor adopts a enlarged hard surface reducer. |

| RV90 | Rubber roller conveying motor and shear motor adopts a enlarged worm gear reducer. | |

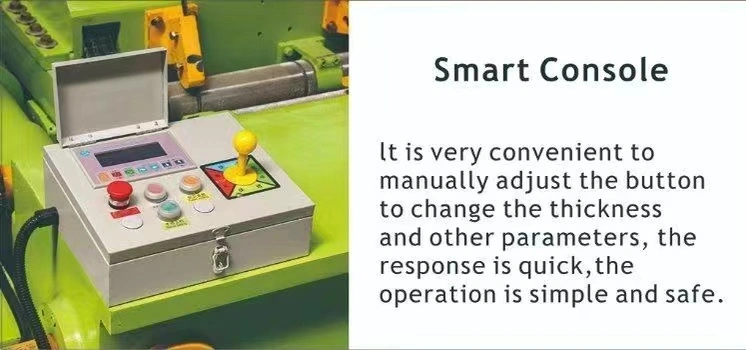

| Main fuction | Unmanned boot system;Advance and retreat knife automatically and quickly;Cast iron tool post; | |

| A whole set of entire imported pneumatic;Siemens electronic control system; | ||

| High alloy screw and tin bronze nut;Automatic fuction of fuel feeding, lubrication,applying butter; | ||

| Hydraulic knife clip;High knife without adjustment; 8.8 high strength bolt of whole machine; | ||

| HIWIN;Thickening chrome-plating roller with lumina finely reticulate and tempered managment; | ||

| Both sides of board surface lights;Plus or minus 0.05mm rotary-cut accuracy;Remaining tail plate automatic cutting fuction; | ||

Detailed Photos

Certificate show

The products have passed the national quality,safety,environmental protection, and mearsurement standard certification EU CE,BV certification.Cooperation show

Packaging & Shipping

Company Profile

Shandong Xuanjin Machinery was formerly established in 2006, Feixian County Jinli Peeling machine factory, in 2015 set up a registered capital of 80 million yuan,in July 2017,it was successfully listed in Qilu Stock Exchange Center.In December 2018,it setablished "Xuanjin Intelligent Equipment Research Institute" based on wood insttitute of Chinese Academy of Forestry,Beijing Forestry University,Wood Institute of Shandong Academy of Forestry and other units,introducing the structural adjustment and industrial upgrading development of woodworking field at home and abroad.The institute is committed to the development of high-end wood equipment manufacturing ,in order to promote Linyi wood and equipment manufacturing industry brand upgrade and promotion. We've been working on the development and manufacture of plywood equipment, The products are mainly exported and are exported to more than 50 countries such as Russia, Egypt, Indonesia, Malaysia, India, Vietnam, Pakistan and so on.

FAQ

Q1: Can you customize products for clients?A1: Yes We can customize and produce woodworking machines according to the customer's requirements or drawings.

Q2:What about your products quality?A2:We can provide you samples for quality inspection. If you order, we guarantee the quality is same with sample. In case of quality problem, we can sign agreements and our company will perform the duties.

Q3:How can we trust your factory?A3:We recommend that you come to our factory to see the goods,to verify the real situation of the products, and know more about our factory.

Q4:Why does the price often change?A4:The price depends on the latest prices of the raw materials.

Q5:What about the contract signing?A5: If you're satisfied with the products and our service, you can sign the contract with us, pay the deposit Then we'll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

Q6: How about delivery?

A: when the product is ready, it can be delivered to you after your full payment. We provide technical guidance.

Why Choose us

1.Since its establishment in2016,our factory has been producing and manufacturing for 16 years,making it a leading enterprise in this industry in China.2.The company has more than 100 employees,among them 28 are science and technology r&d personnel.In 2016, it was awarded the national high-tech enterprise.By 2022,it has successively obtained more than 100 national patents,including nearly 10 national invention patents.Two of the company's patented products have been evaluated as international advanced level by the Ministry of Science and Technology.The company has participated in the formulation of three national industry standards,and has passed ISO9001 quality management system,measurement management system and European CE certification. 3.Our company can send labor services abroad to provide one-to-one guidance for the use and operation of customers' products.Technical personnel can stay in the country of customers to teach and guide customers to skillfully use the machine.4.Our company pays great attention to detail control, our company is the only manufacturer that uses 8.8 nut, which has simple construction and good machanical performance,removeable resistant to fatigue,not loosened under dynamic load;The machine wiht photoelectric detector,it can self-sensing wood; Parts laser cutting, cutting size standard, smooth edge mouth,it has obvious advantages over flame cutting.5.Our company provides customers with all aspects of pre-sale,sale and after-sales services,so that customers have no worries.The boards can be repurchased,so that customers do not have to worry about sales.

Pre-sale service1) Provide the free consultation of equipment2) Provide the standard device and the flow chart3) According to the clients' special requirement ,offering the resonable plan and free design to help to select the equipment .4)Welcome to visit our factoryService during the sales1) Inspect the machine before leaving the factory2) Oversea install and debug the equipment3) Train the first-line operatorAfter sales service1) 24 hours online service2) Provide the VIDEO with install and debug the equipment3) Provide technical exchanging

Related Products

-

![1000W 2000W 3000W Metal Sheet Mild Stainless Steel Aluminum Copper Cutter Ipg CNC Fiber Laser Cutting Machine]()

1000W 2000W 3000W Metal Sheet Mild Stainless Steel Aluminum Copper Cutter Ipg CNC Fiber Laser Cutting Machine

-

![Fiber/CO2/UV Laser Engraving Machine/Laser Marker Machine/Engraving Equipment/Logo Printing Machine Laser Marking Machine for Metal/Plastic/Wood]()

Fiber/CO2/UV Laser Engraving Machine/Laser Marker Machine/Engraving Equipment/Logo Printing Machine Laser Marking Machine for Metal/Plastic/Wood

-

![10/20/30/50W Diode Pumped Laser Marking Machine Manufacturer]()

10/20/30/50W Diode Pumped Laser Marking Machine Manufacturer

-

![Plastic Printing Machine for Bottles Cups Phone Cases Clearly Photo]()

Plastic Printing Machine for Bottles Cups Phone Cases Clearly Photo